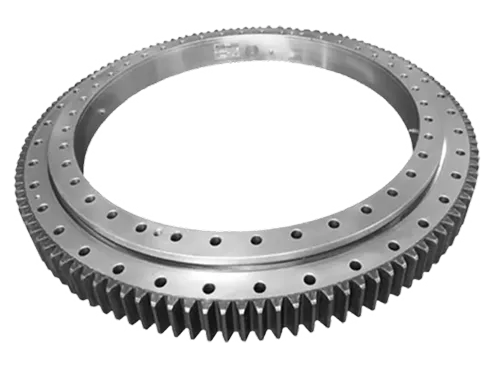

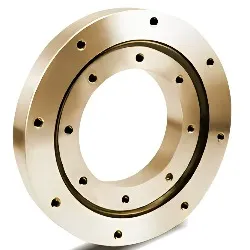

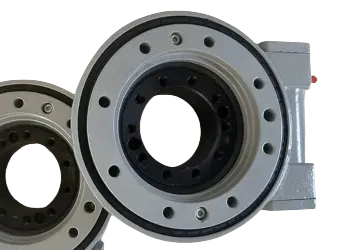

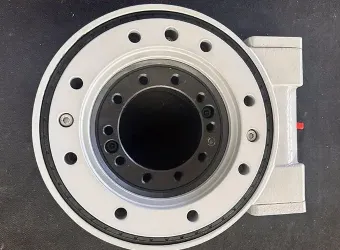

Slewing Drive, also known as a rotary reducer and rotary reducer, is a full-circumferential slewing reduction transmission mechanism integrating driving power source. It uses the slewing support as the transmission follower and mechanism attachment. By attaching the active member, the driving source and the cover to one of the inner and outer rings, the other ring is used as the transmission follower and the connecting base to achieve the integration of rotation, reduction and driving functions.

According to the variable speed transmission form, it can be divided into toothed rotary drive and worm gear and worm rotary drive. The former has high transmission efficiency, while the latter has a large reduction ratio and self-locking function. Its core components are made of high-quality steel, and the worm gear and worm are desalinated by glow ion, which can withstand axial, radial and tilt torques. The mechanism adopts a modular design, simple structure and easy to manufacture and maintain. It is divided into multiple series, and can provide non-standard customization services and is equipped with electromagnetic brakes to reduce the moment of rotation. The worm gear and worm rotary drive has the characteristics of IP65 protection level and strong impact resistance. It is used in engineering machinery slewing structures, solar tracking devices, industrial robots and wind power generation equipment to meet the needs of large torque transmission and compact structures.