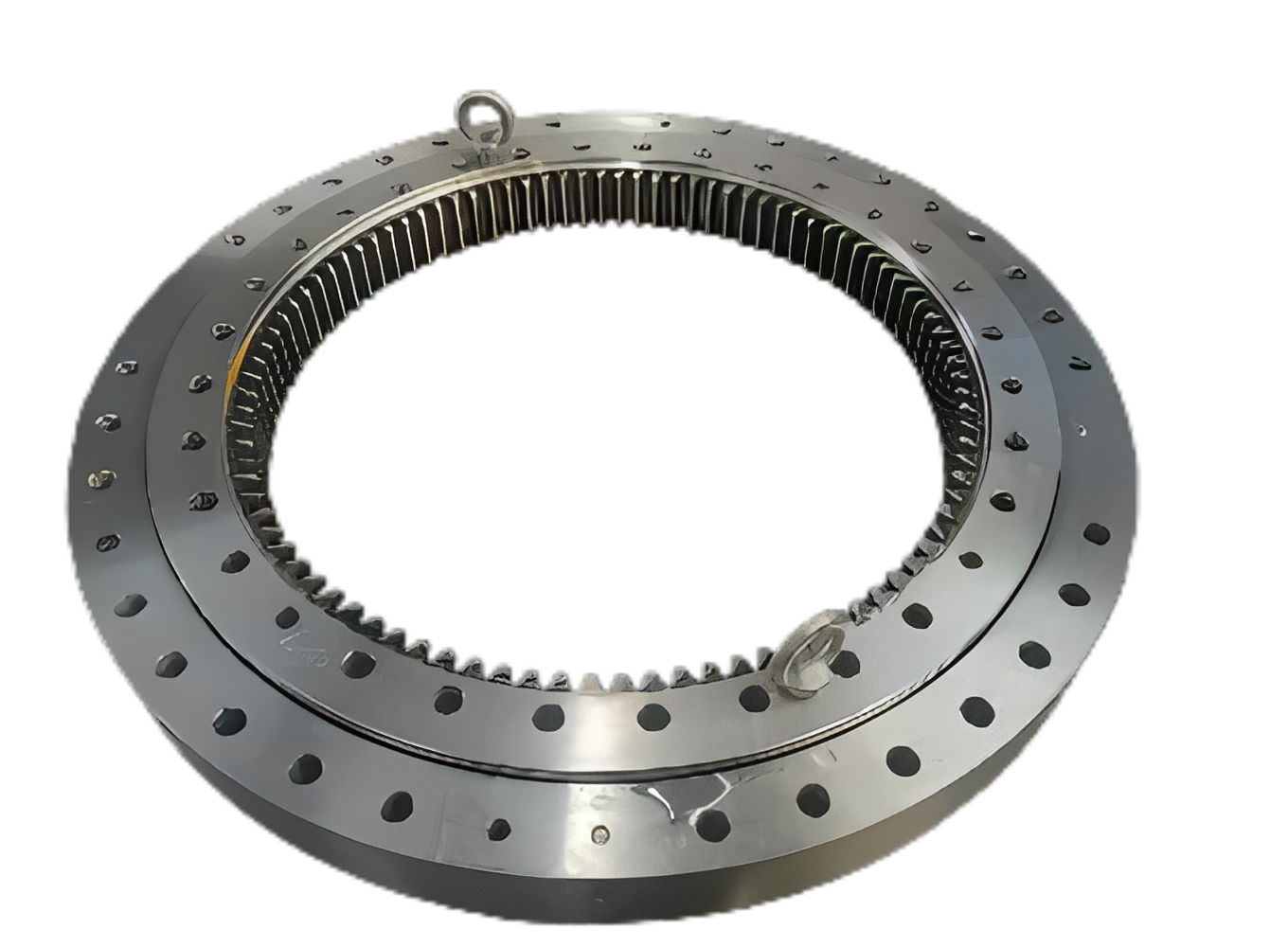

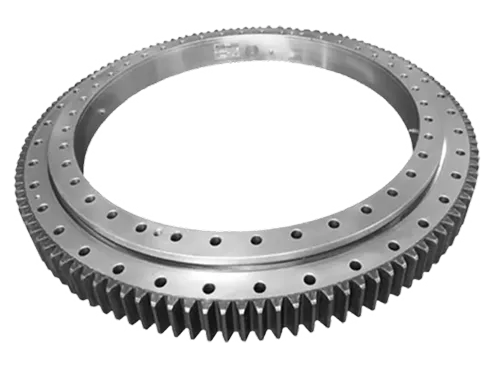

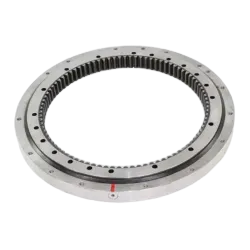

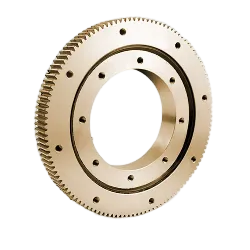

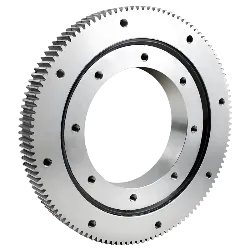

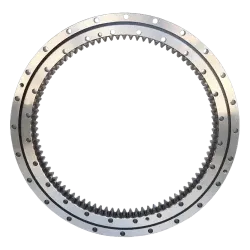

- 1. Single row four-point contact ball slewing bearing

- 01 series

- HS series

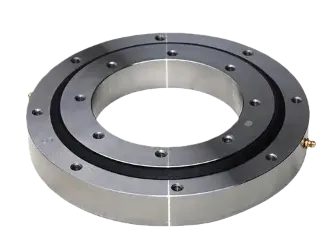

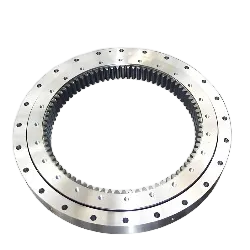

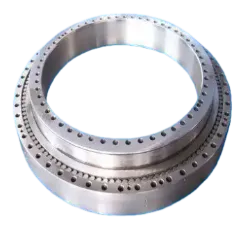

- 2. Cross roller slewing bearing

- 11 series

- HJ series

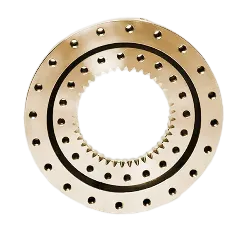

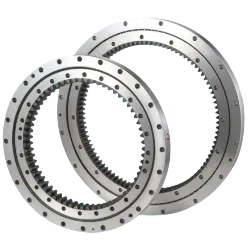

- 3. Double volley ball slewing bearing

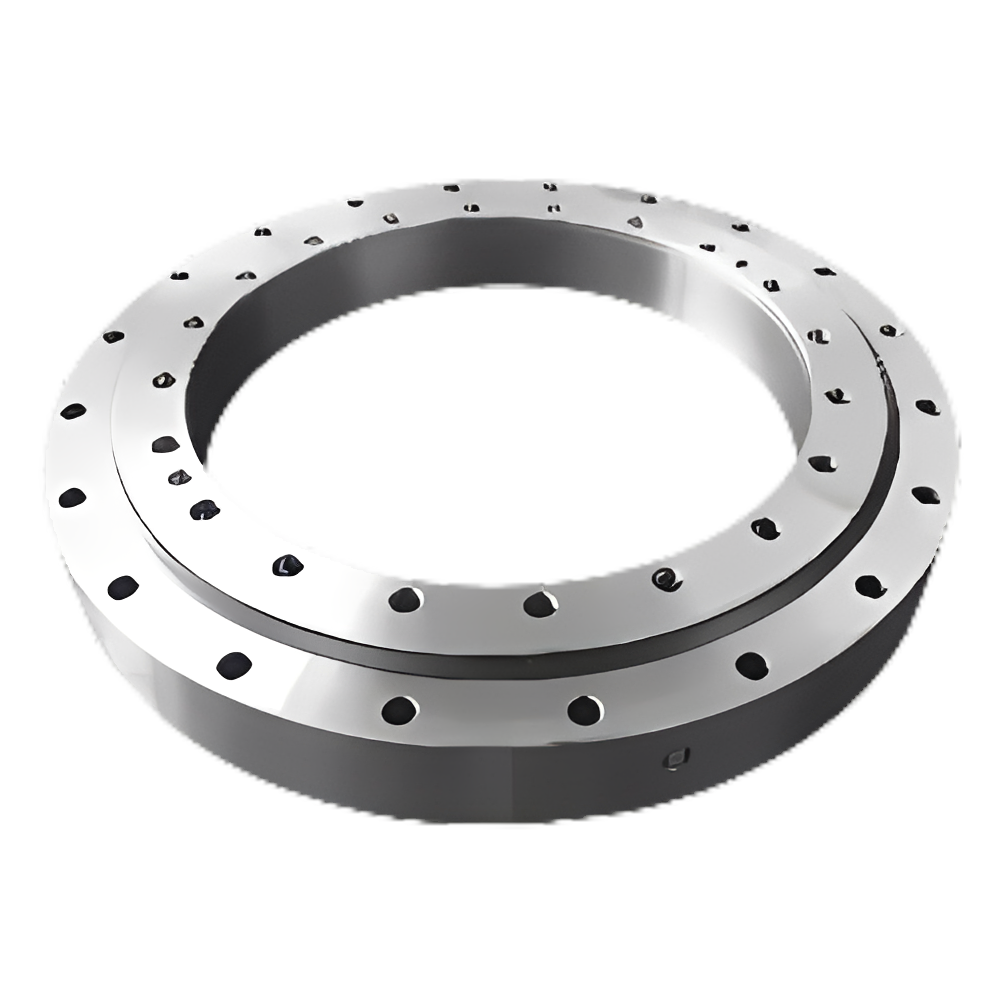

- 4. Double row ball slewing bearing

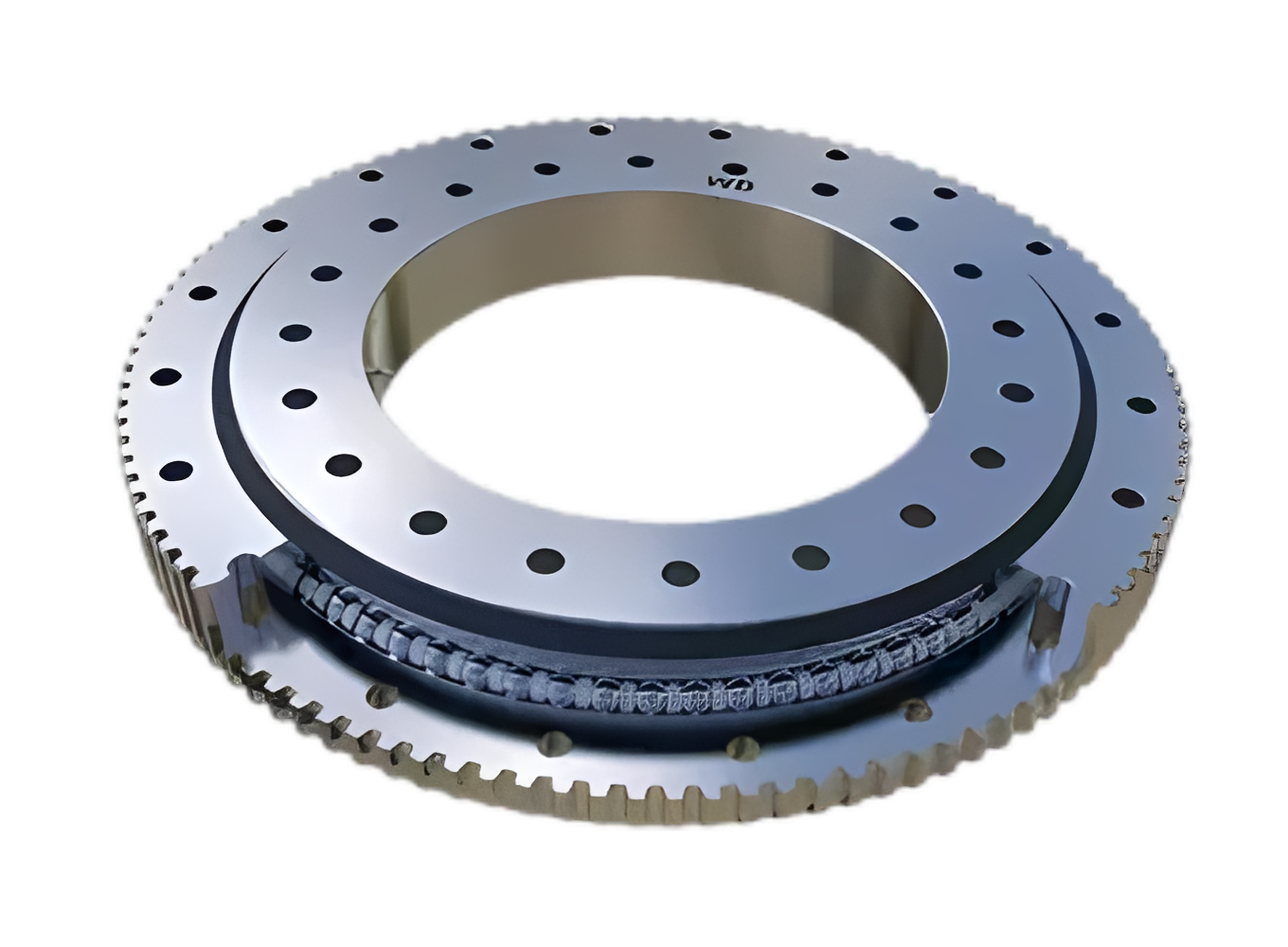

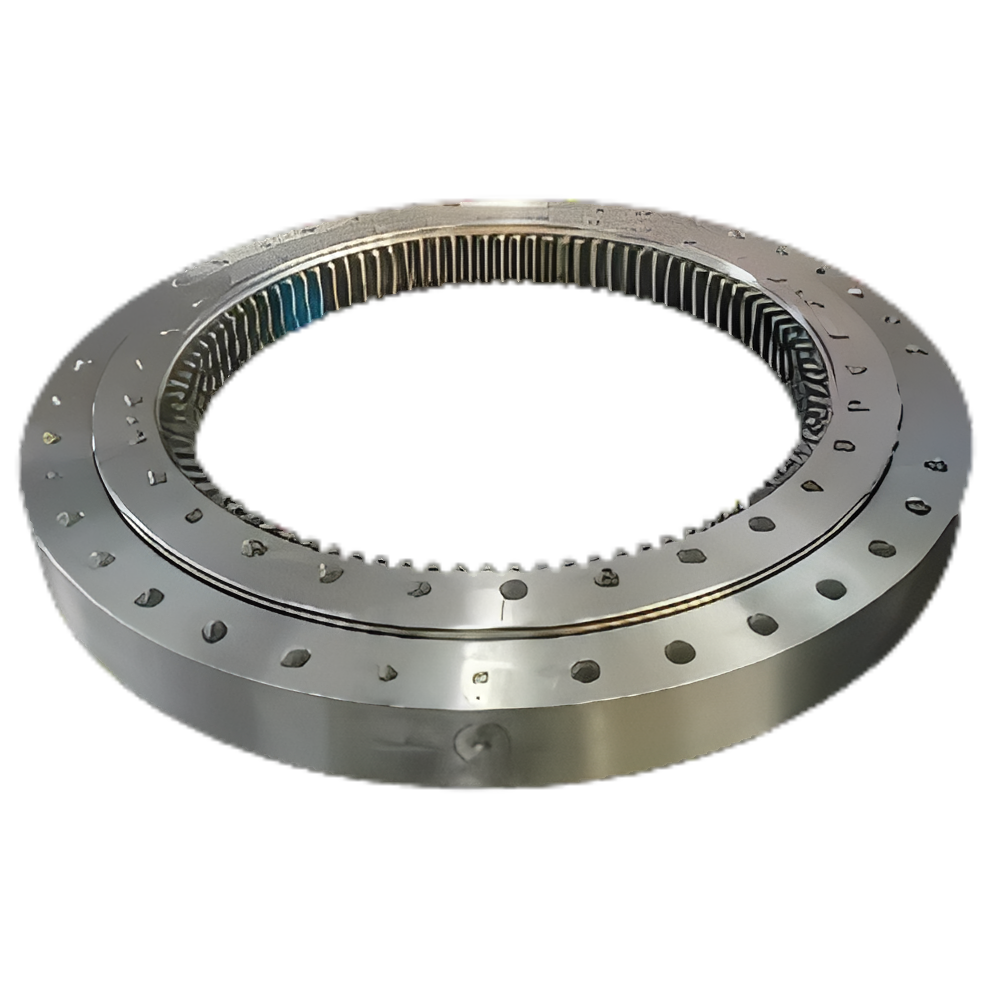

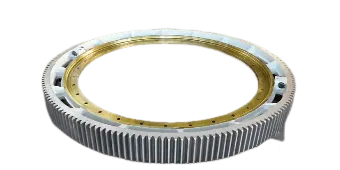

- 5. Three rows of roller slewing bearings

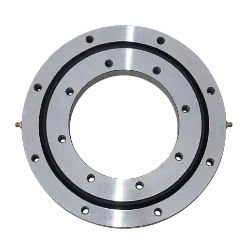

- 6. Light and thin series slewing bearings (specially customized)

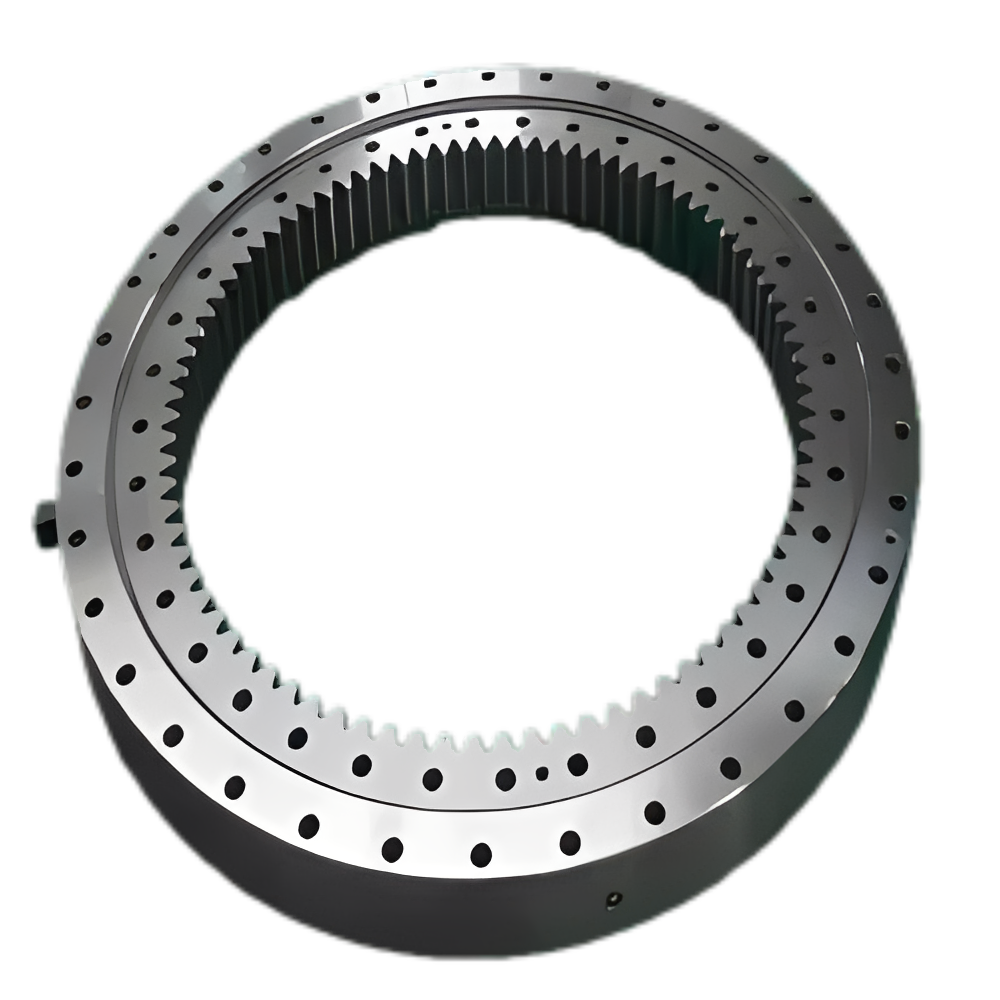

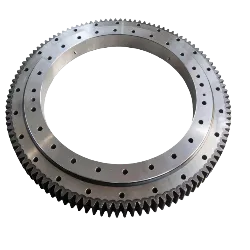

- 7. Excavator slewing bearing series

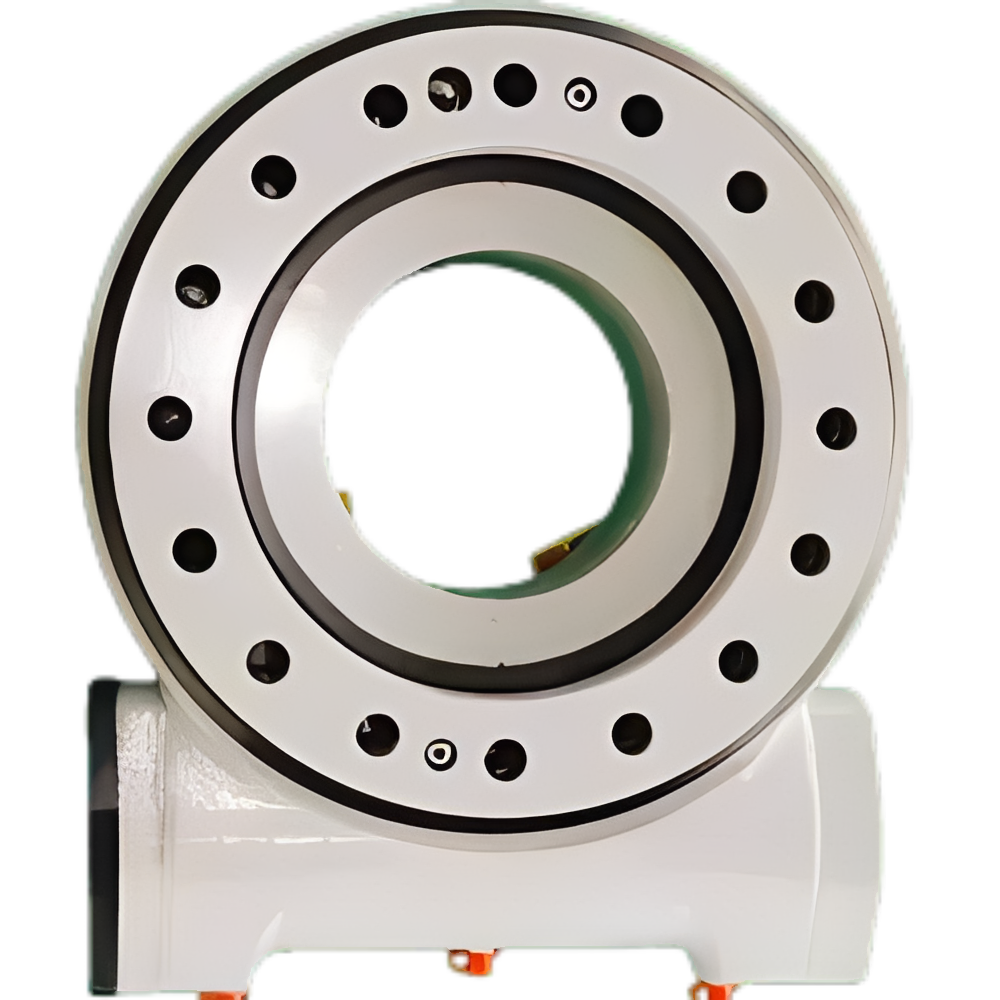

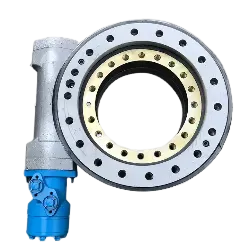

- 8. Rotary drive series

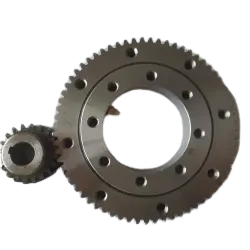

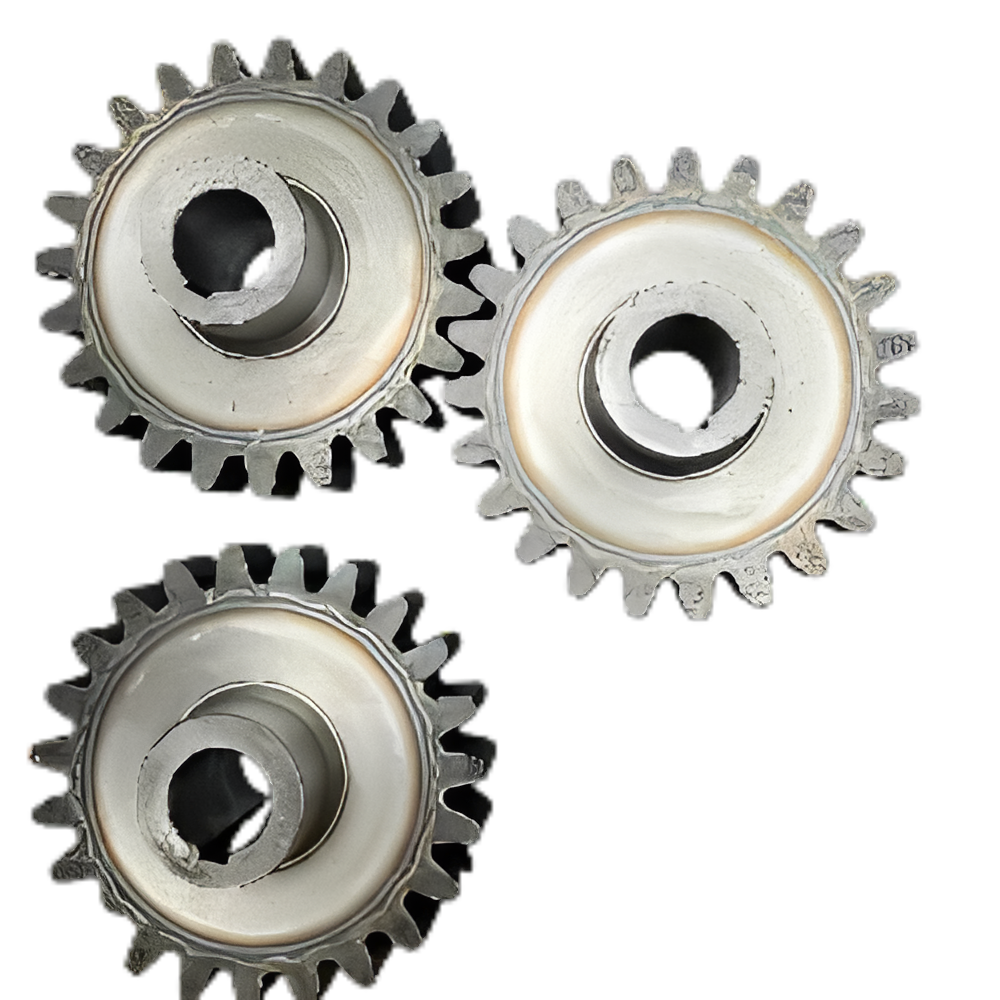

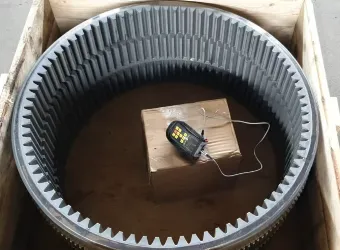

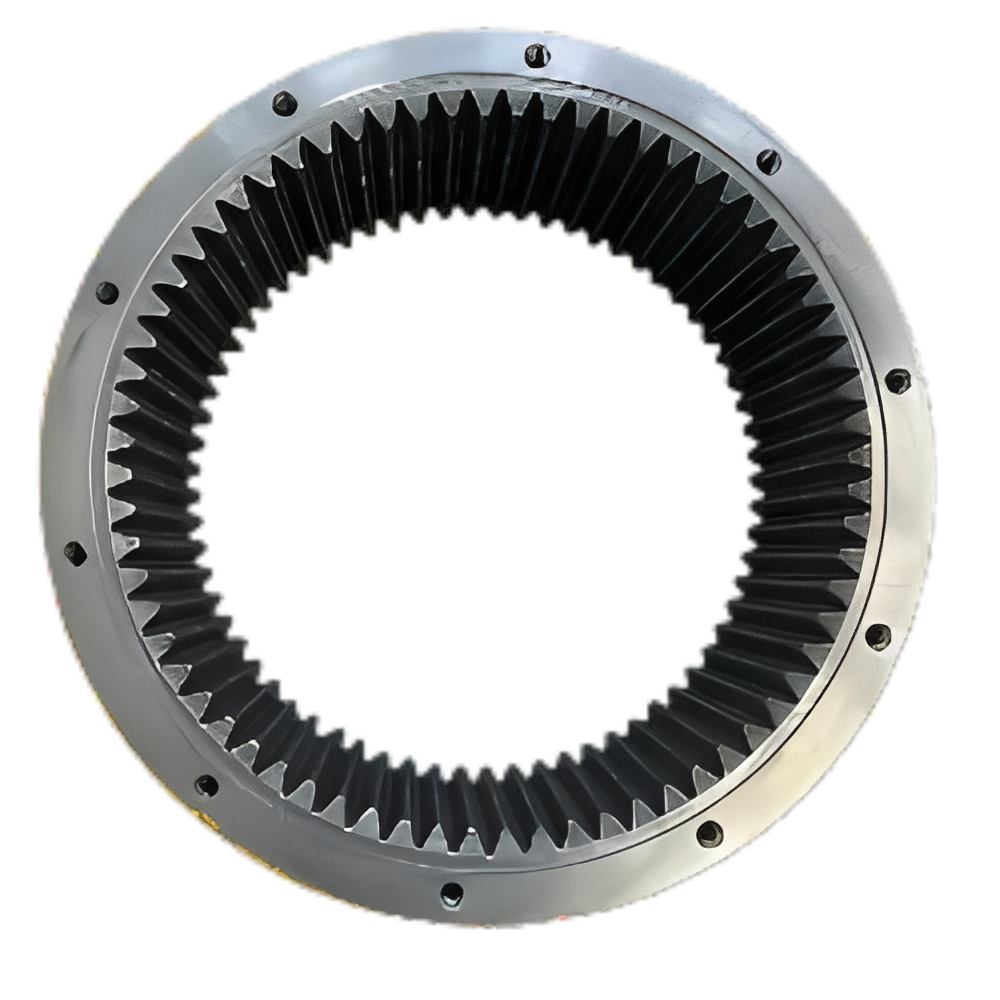

- 9. Matching gears and ring gears

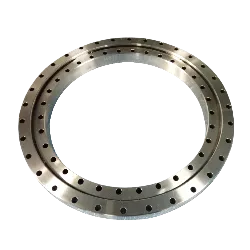

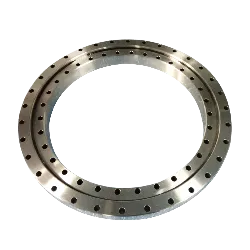

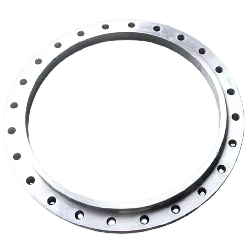

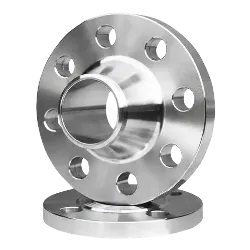

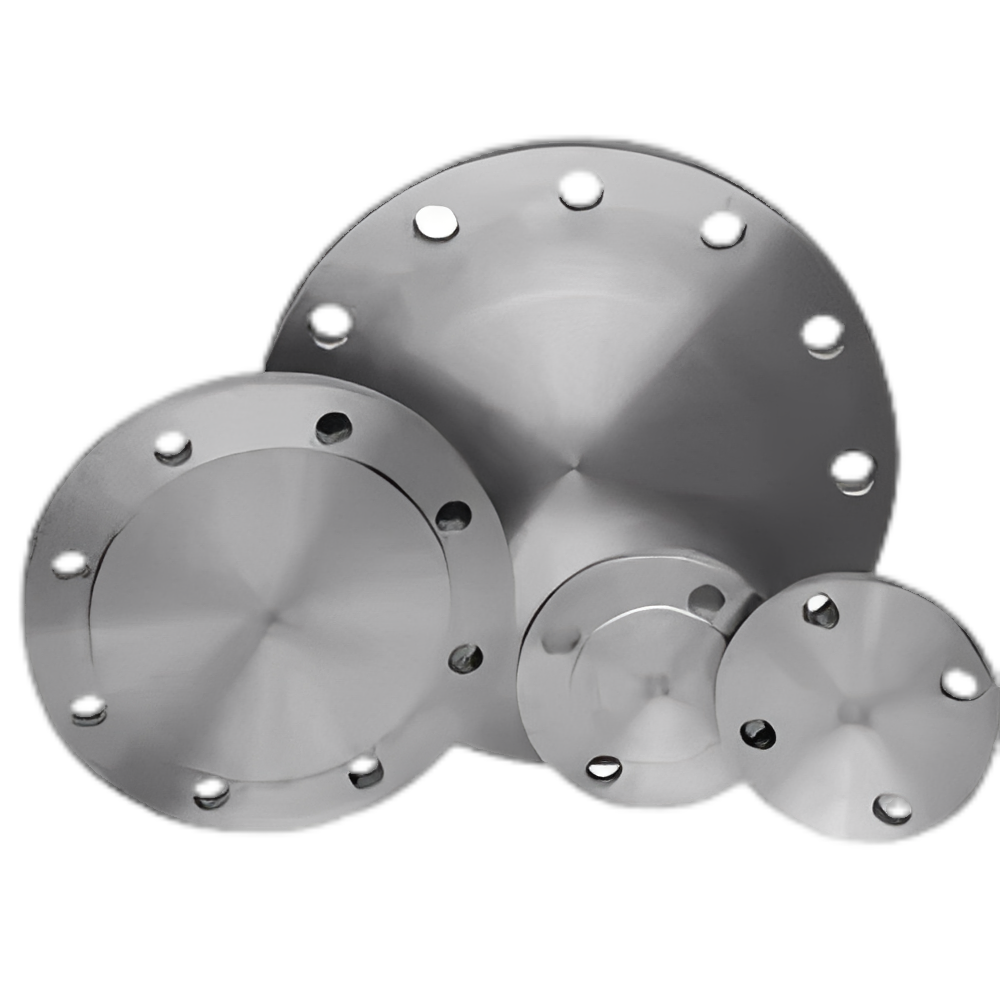

- 10. Flange

- 11. Flange plate (cover)

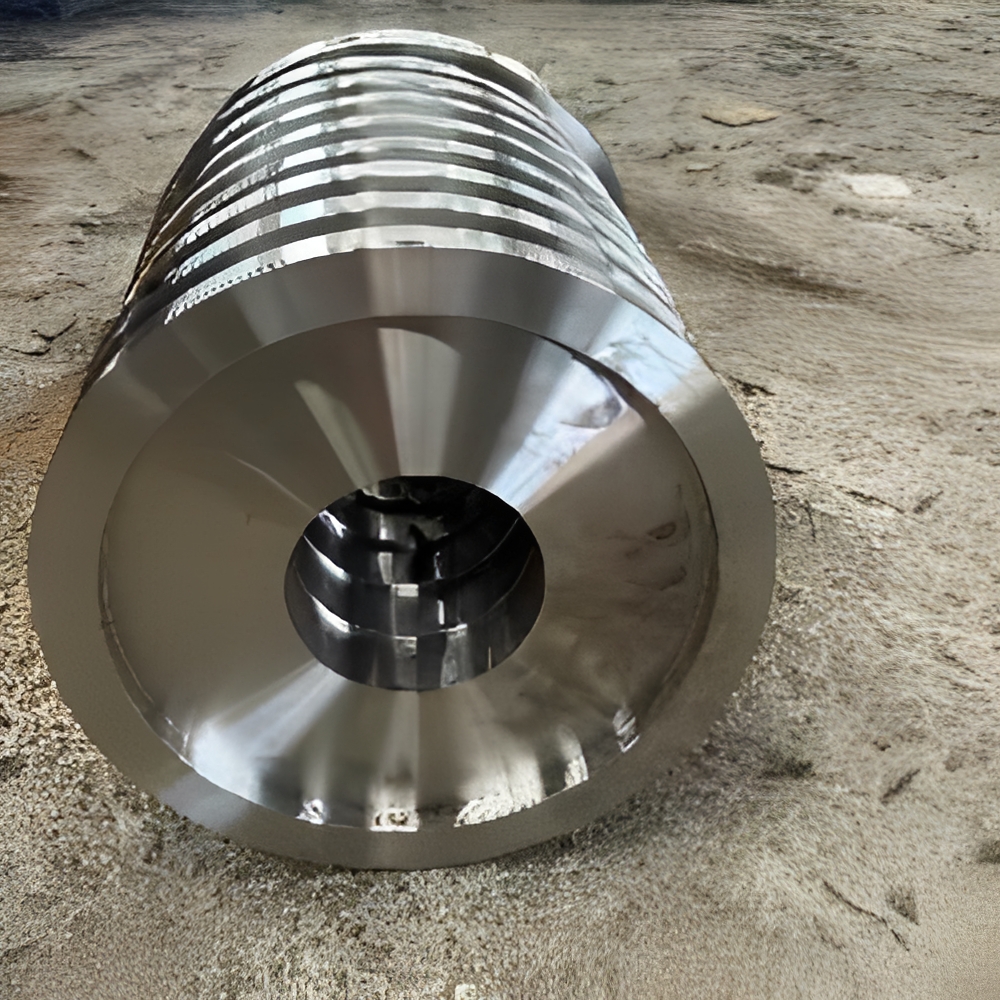

- 12. Ring forgings

WHAT YOU ARE LOOKING FOR?

Quick Links