Shandong Yongqiang Precision Forging Co., Ltd. was rated as a national high-tech enterprise. Recently, Shandong Yongqiang Precision Forging Co., Ltd. successfully passed the high-tech enterprise review and certification jointly organized by the Shandong Provincial Department of Science and Technology, the Department of Finance, and the State Administration of Taxation and the Shandong Provincial Taxation Bureau, and was officially rated as a "National High-tech Enterprise."

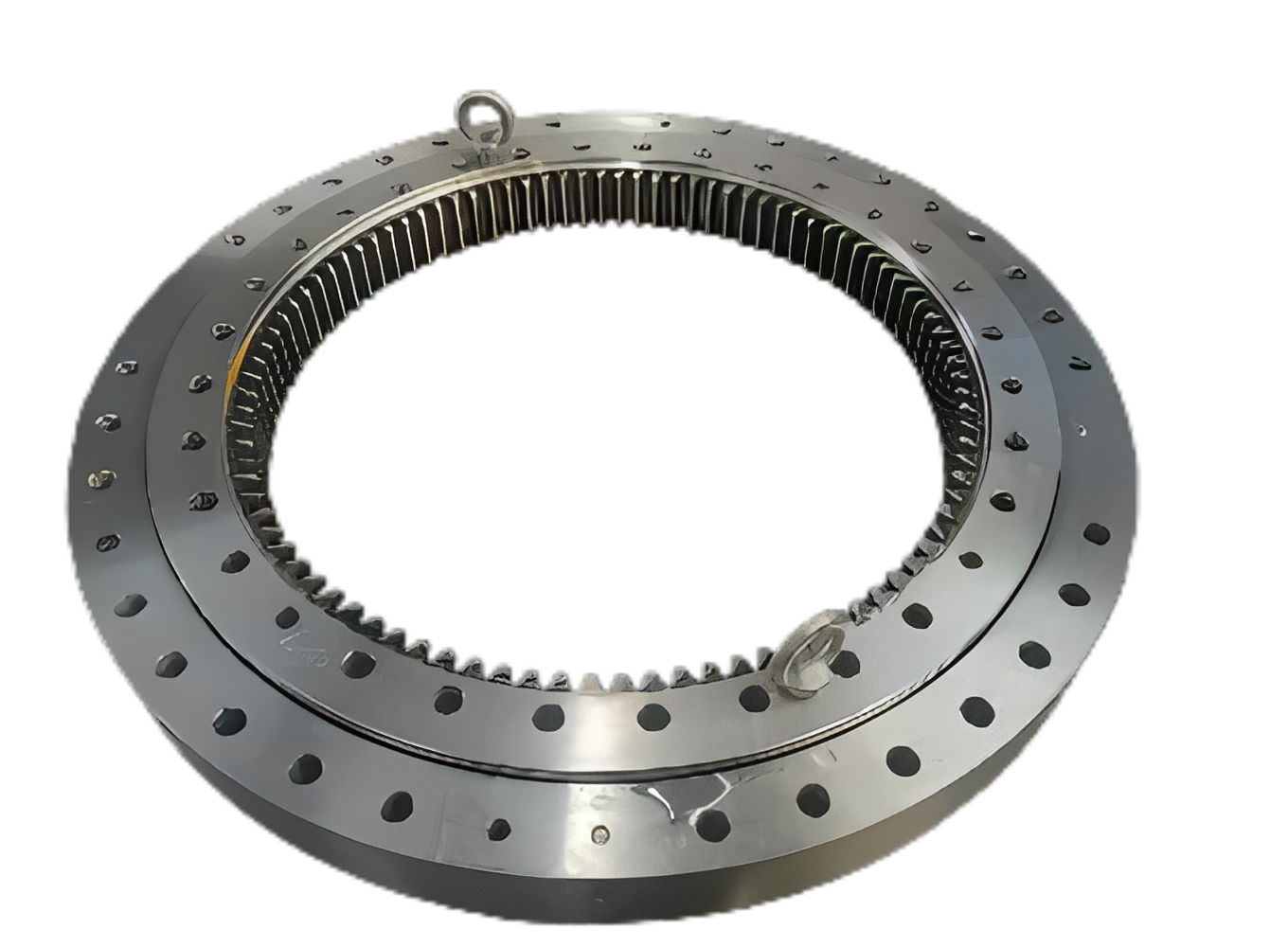

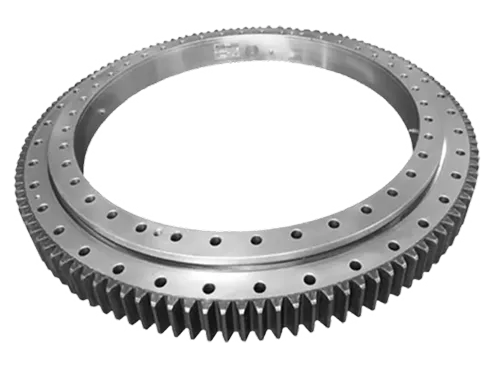

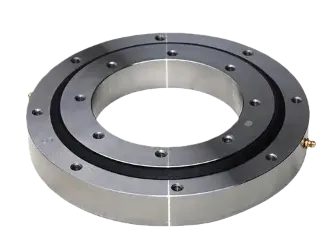

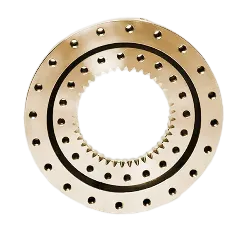

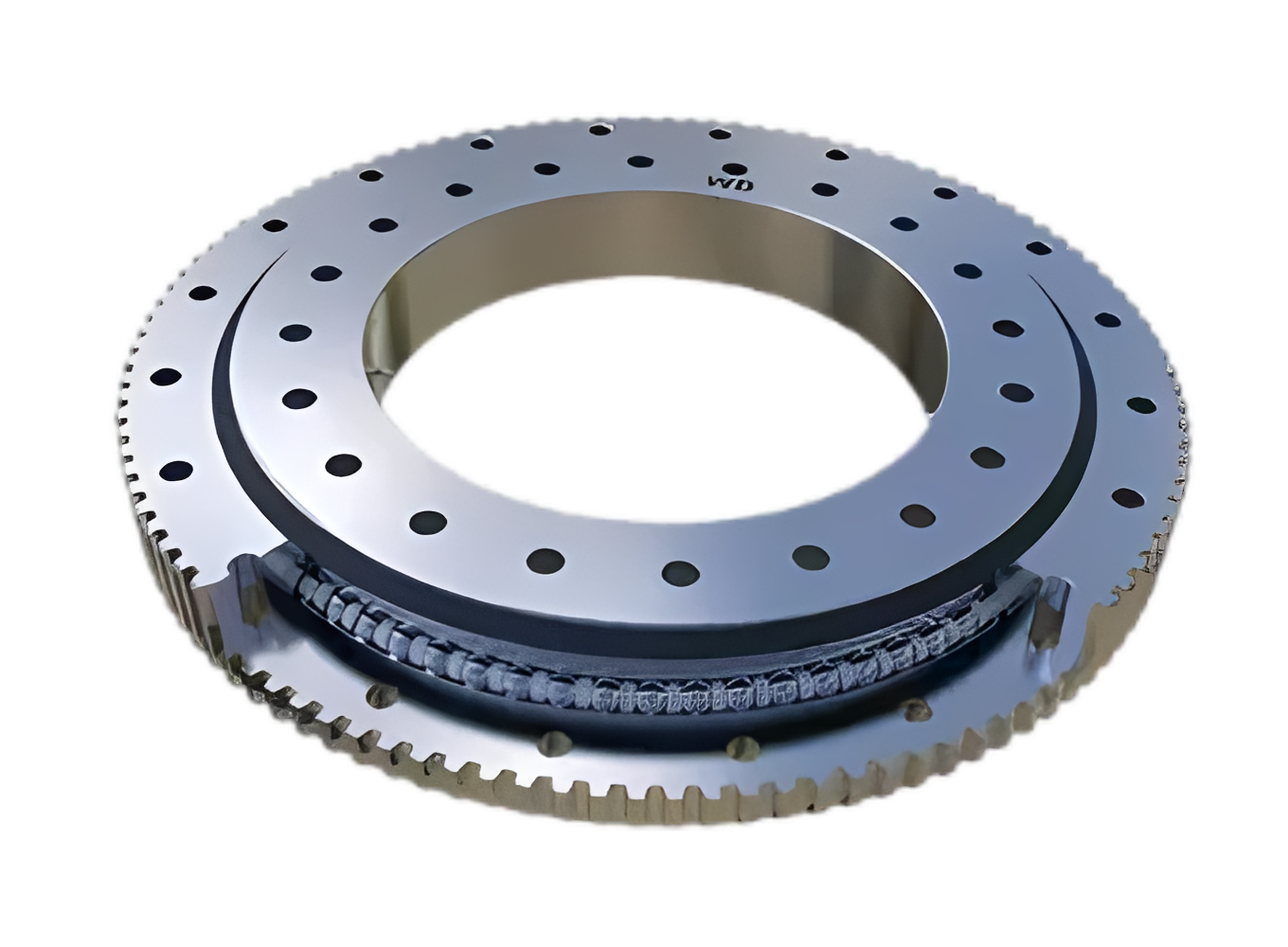

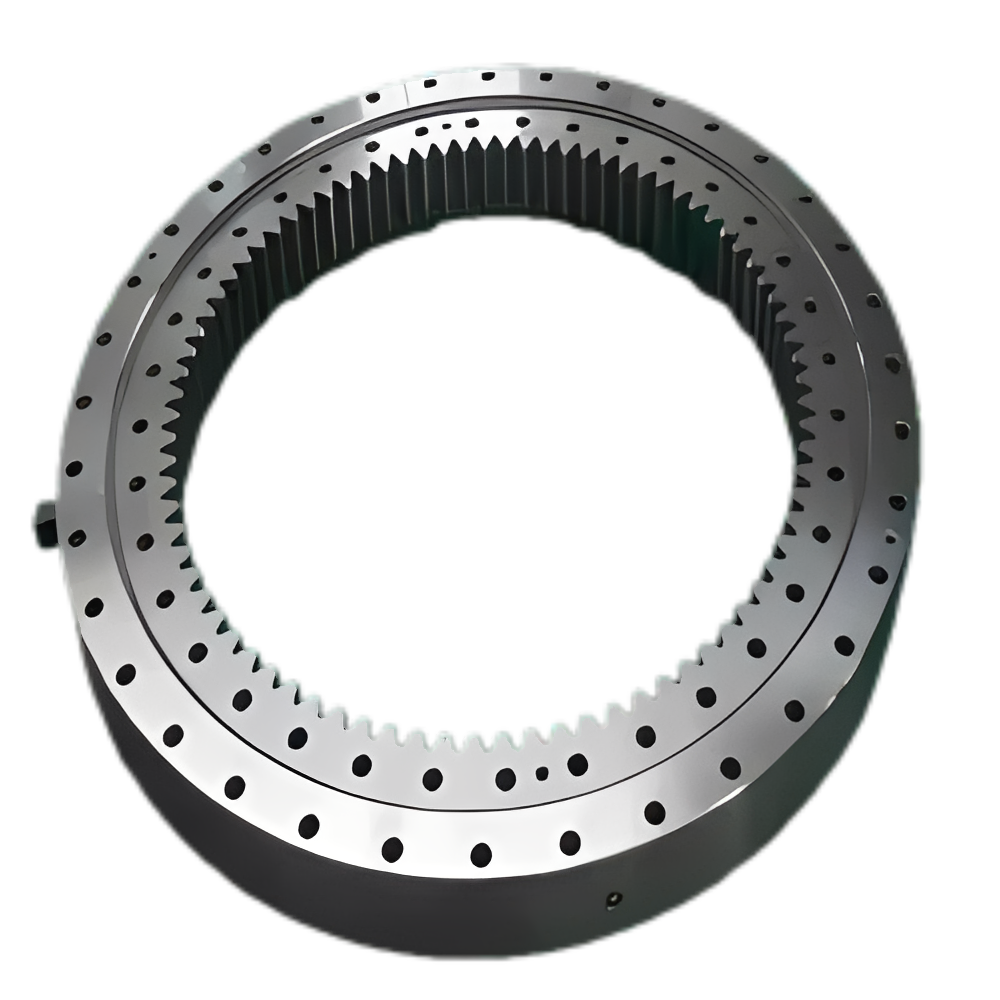

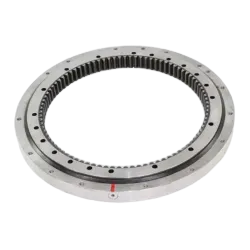

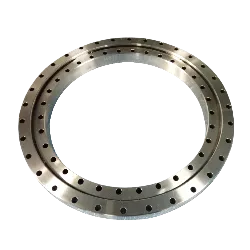

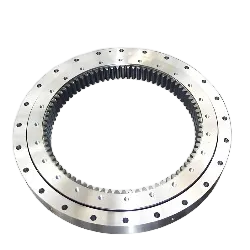

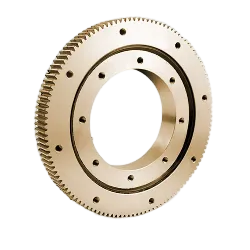

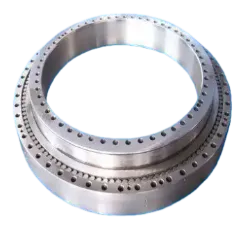

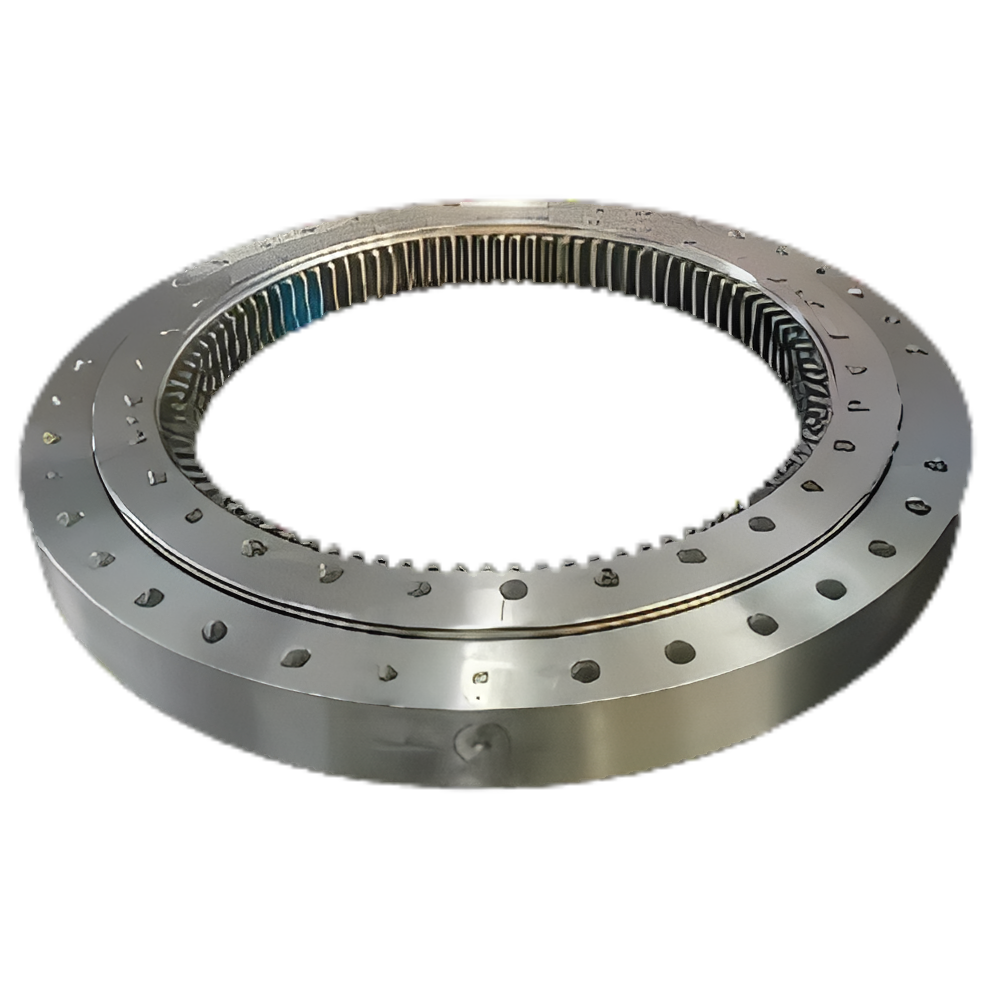

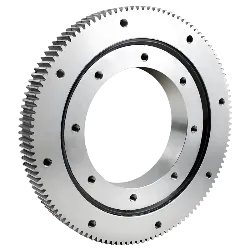

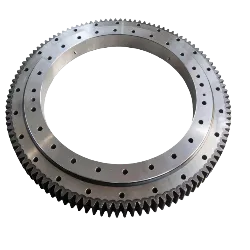

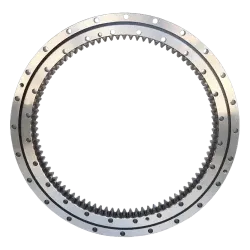

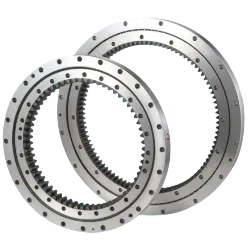

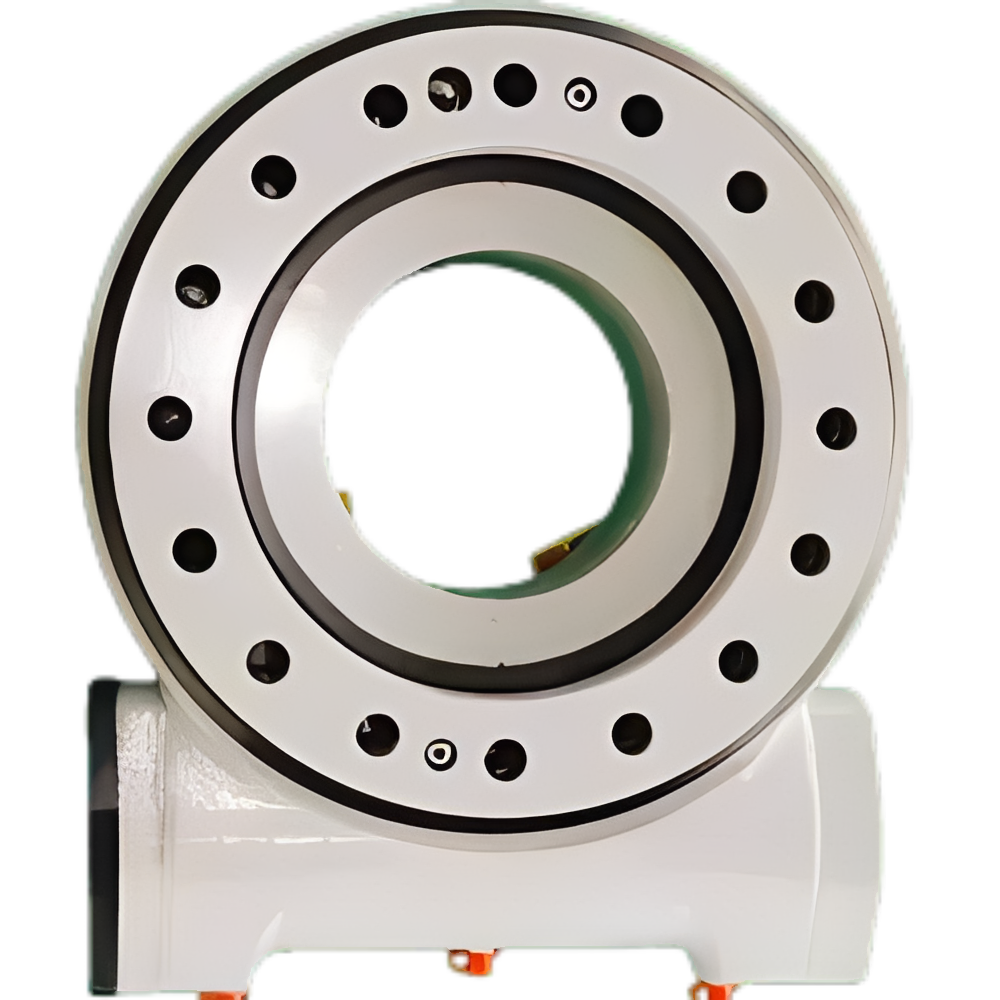

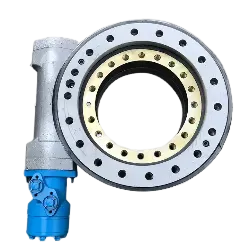

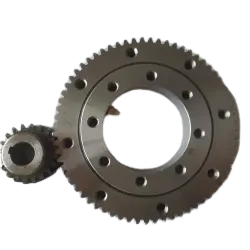

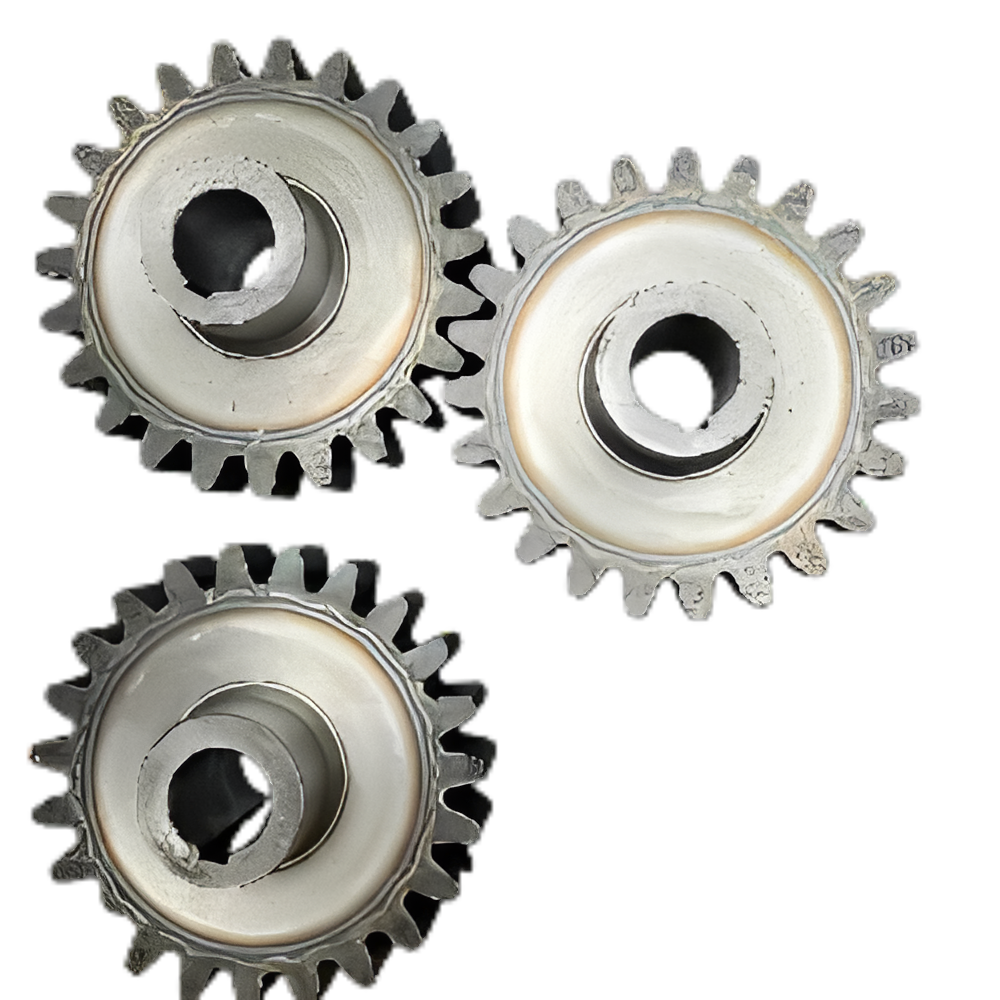

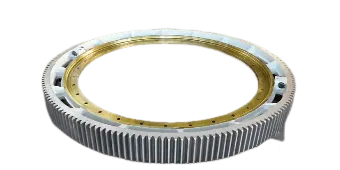

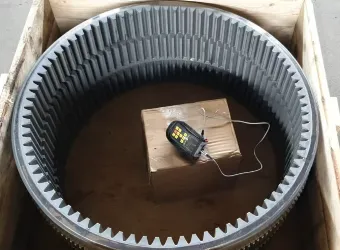

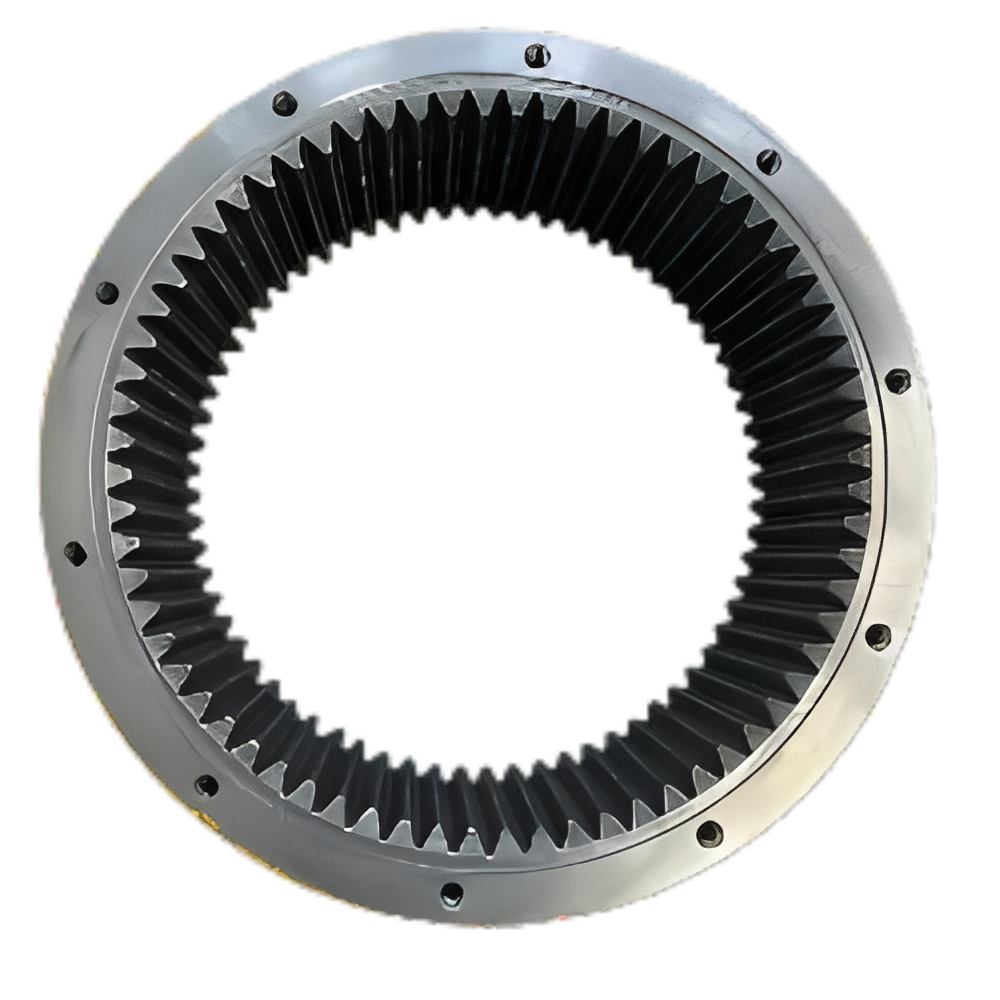

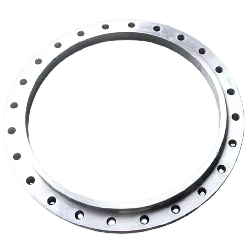

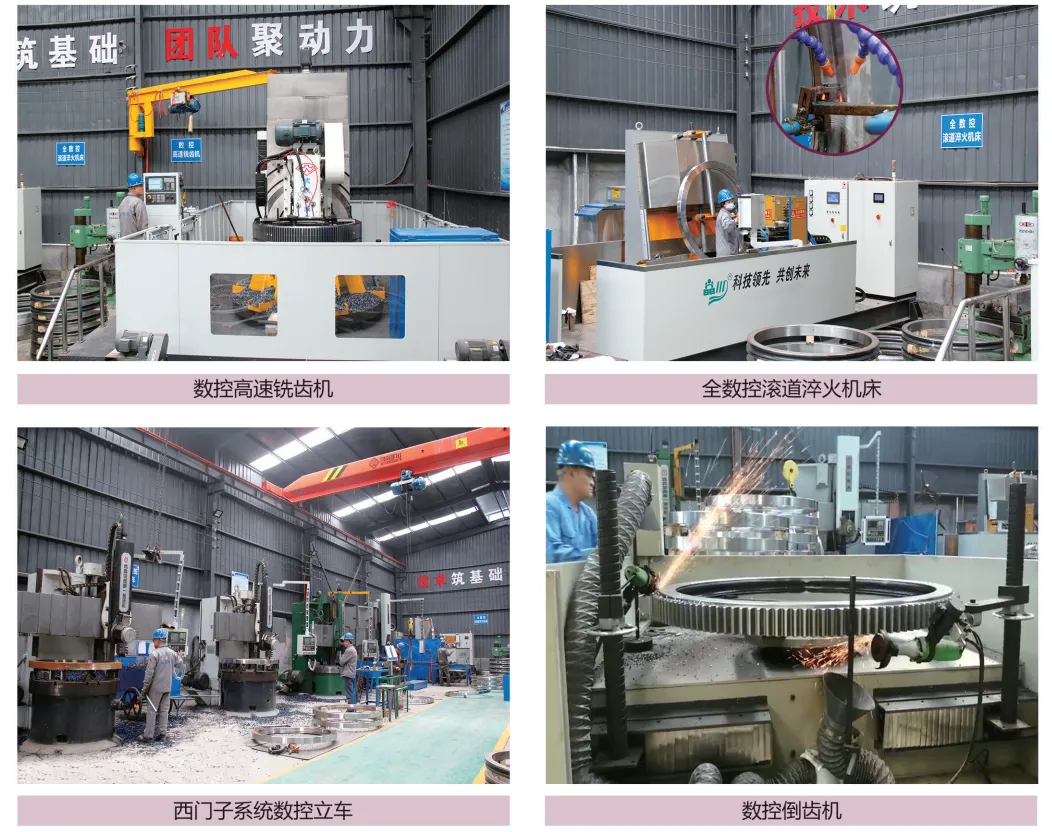

This certification is an authoritative recognition of the company's scientific and technological innovation capabilities and core technical strength. For a long time, Yongqiang Precision Forging Company has insisted on being driven by technological innovation, continuously increasing investment in research and development, actively promoting the transformation of scientific and technological achievements, and forming stable technical advantages in the field of slewing bearings and forging product processing.

In the future, Yongqiang Precision will use this award as a new starting point to continue to deepen technology research and development and product innovation, continuously improve its core competitiveness, provide customers with higher-quality products and services, and help the high-quality development of the industry.